US Businesses Brace for Predicted Shipping Cost Increase: Supply Chain Strategies

US Businesses: As shipping costs are predicted to increase by 10% in the next quarter, US businesses must assess and adapt their supply chain strategies to mitigate the impact on profitability and maintain competitiveness.

Prepare your **US Businesses: Is Your Supply Chain Ready for the Predicted 10% Increase in Shipping Costs in the Next Quarter?** by understanding the factors driving this surge and implementing proactive strategies.

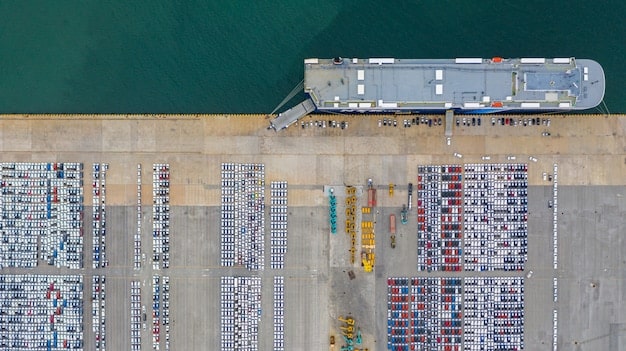

Understanding the Looming Shipping Cost Hike

The shipping industry is complex and influenced by numerous factors. Understanding the root causes of the predicted 10% increase in shipping costs is crucial for US businesses.

Key Factors Driving Cost Increases

Several factors contribute to the rising costs of shipping, each requiring careful consideration for businesses aiming to manage their supply chains effectively.

- Increased Demand: A surge in consumer demand, particularly for e-commerce, places significant strain on shipping capacity.

- Fuel Prices: Fluctuations in fuel prices directly impact shipping costs, as carriers pass on these expenses to customers.

- Geopolitical Instability: Global events and political tensions can disrupt shipping routes and increase insurance premiums, leading to higher costs.

- Labor Shortages: Shortages of truck drivers, port workers, and other logistics personnel can cause delays and increase labor costs.

These factors interact in complex ways, creating a volatile environment for businesses reliant on efficient and affordable shipping.

Understanding that external forces also influence shipping costs will allow businesses to be agile.

Assessing Your Current Supply Chain Vulnerabilities

A thorough assessment of your existing supply chain is the first step toward mitigating the impact of rising shipping costs. This involves identifying potential bottlenecks, inefficiencies, and areas of vulnerability.

Identifying Weak Links

Pinpointing weak links within your supply chain can help you prioritize areas for improvement and implement targeted solutions, securing against the growing costs.

- Over-Reliance on Single Suppliers: Depending on a single supplier increases the risk of disruptions and price hikes.

- Inefficient Inventory Management: Poor inventory control can lead to excess stock or stockouts, both of which increase costs.

- Lack of Visibility: Limited insight into your supply chain makes it difficult to identify and address potential issues proactively.

- Outdated Technology: Using outdated systems can hinder efficiency and increase the risk of errors.

Address the vulnerabilites by looking for alternative solutions to offset costs.

Strategies for Negotiating Better Shipping Rates

Negotiating favorable shipping rates is a critical component of managing costs. US businesses can leverage several strategies to secure better deals with carriers.

Negotiations can allow for a better grasp on your budget.

Tips for Successful Negotiation

Effective negotiation involves preparation, knowledge, and a willingness to explore alternative solutions, improving outcomes that address shipping costs.

- Consolidate Shipments: Combining multiple shipments into fewer, larger loads can reduce costs per unit.

- Negotiate Volume Discounts: Securing discounts based on the volume of shipments can significantly lower overall expenses.

- Shop Around for Carriers: Comparing rates from multiple carriers can help you identify the most competitive offers.

- Build Strong Relationships: Establishing long-term relationships with carriers can lead to more favorable terms and better service.

Negotiating isn’t always about asking for discounts, it is also about finding new solutions that can offset and secure better prices.

Diversifying Your Sourcing and Logistics Network

Diversifying your sourcing and logistics network can reduce your reliance on specific suppliers or carriers, mitigating the impact of disruptions and price increases.

Diversifying can open up new opportunities and allow for more solutions.

Expanding Your Options

Exploring alternative sourcing locations and logistics partners can provide greater flexibility and resilience in the face of rising shipping costs and supply chain challenges.

- Identify Alternative Suppliers: Researching and vetting alternative suppliers in different regions can provide backup options in case of disruptions.

- Explore Regional Logistics Hubs: Utilizing regional distribution centers can reduce shipping distances and costs.

- Consider Nearshoring: Moving production closer to the US can reduce transportation times and expenses.

- Partner with Multiple Carriers: Working with a diverse network of carriers ensures access to capacity and competitive rates.

These steps can significantly mitigate your vulnerabilities.

Investing in Technology to Optimize Supply Chain Efficiency

Technology plays a critical role in optimizing supply chain efficiency and reducing costs. Implementing advanced solutions can improve visibility, streamline processes, and enhance decision-making.

The use of technology is a must for companies to stay ahead.

Leveraging Tech Solutions

Investing in the right technological tools can transform your supply chain, making it more agile, responsive, and cost-effective in the face of rising shipping expenses.

There are several aspects where technology can be beneficial:

- Transportation Management Systems (TMS): TMS platforms optimize route planning, carrier selection, and shipment tracking, reducing transportation costs.

- Warehouse Management Systems (WMS): WMS solutions improve inventory management, order fulfillment, and warehouse operations, minimizing waste and increasing efficiency.

- Supply Chain Analytics: Predictive analytics tools can forecast demand, identify potential disruptions, and optimize inventory levels.

- Blockchain Technology: Blockchain enhances transparency and security in the supply chain, reducing fraud and streamlining transactions.

Adapting and implementing technology isn’t as hard, costly, or scary as it seems.

Building Resilience Through Collaborative Partnerships

Collaborative partnerships with suppliers, carriers, and customers can enhance resilience and mitigate the impact of rising shipping costs. Sharing information and resources can improve efficiency and reduce risk.

Working with others, allow for new outlooks and ideas.

Fostering Collaboration

Building strong, collaborative relationships throughout your supply chain can create a more resilient and adaptable network, better equipped to manage rising costs and unexpected disruptions.

- Sharing Forecasts and Information: Sharing demand forecasts and shipping information with suppliers and carriers can improve planning and reduce lead times.

- Joint Problem Solving: Collaborating with partners to identify and address supply chain challenges can lead to innovative solutions.

- Long-Term Contracts: Establishing long-term contracts with suppliers and carriers can provide price stability and ensure access to capacity.

- Joint Investment in Technology: Collaborating with partners to invest in technology solutions can improve efficiency and reduce costs across the supply chain.

Collaboration allows for new and creative solutions can be discovered.

| Key Point | Brief Description |

|---|---|

| 🚢 Shipping Cost Hike | Understanding the predicted 10% increase in shipping costs is crucial. |

| 📊 Supply Chain Assessment | Assess vulnerabilities to identify bottlenecks and inefficiencies. |

| 🤝 Negotiation Strategies | Negotiate better rates by consolidating shipments and building relationships. |

| 🌐 Diversification | Diversify sourcing and logistics networks to reduce reliance on single points. |

FAQ

Increased demand due to e-commerce, fluctuating fuel prices, geopolitical instability, and labor shortages are key factors impacting shipping costs.

Businesses should identify over-reliance on single suppliers, inefficient inventory management, lack of visibility, and outdated technology.

Consolidate shipments, negotiate volume discounts, shop around for carriers, and build strong relationships with carriers to secure favorable terms.

Diversifying reduces reliance on specific suppliers or carriers, which mitigates the impact of disruptions and price increases.

Transportation and warehouse management systems improve processes. Predictive analytics help forecast demand and blockchain tech enhances supply chain security.

Conclusion

Navigating the predicted 10% increase in shipping costs requires US businesses to proactively assess their supply chains, implement strategic negotiations, diversify their networks, invest in technology, and foster collaborative partnerships to build resilience and maintain competitiveness.