The Impact of 2025 EPA Regulations on US Manufacturing

The Impact of the 2025 US Environmental Protection Agency (EPA) Regulations on Manufacturing is expected to be significant, influencing operational costs, technological advancements, and overall competitiveness within the US manufacturing sector as companies adapt to meet the new standards.

As 2025 approaches, the US manufacturing sector is bracing for a significant shift driven by new environmental regulations from the Environmental Protection Agency (EPA). These regulations are designed to enhance environmental protection and public health, but they also pose challenges for manufacturers who must adapt their processes and technologies.

Understanding the Impact of the 2025 US Environmental Protection Agency (EPA) Regulations on Manufacturing is crucial for businesses looking to maintain competitiveness and sustainability. This article delves into the specifics of these regulations, their potential effects, and strategies for manufacturers to navigate this evolving landscape.

Understanding the 2025 EPA Regulations

The Environmental Protection Agency (EPA) continuously updates its regulations to address emerging environmental challenges and improve public health. The 2025 regulations are expected to focus on reducing emissions, improving water quality, and managing hazardous waste. These changes will impact various aspects of the manufacturing industry. The goal is to promote cleaner production processes and a more sustainable industrial sector, but how will the Impact of the 2025 US Environmental Protection Agency (EPA) Regulations on Manufacturing play out?

Key Areas of Regulatory Focus

The upcoming regulations are likely to target several critical areas within manufacturing operations. Understanding these areas is the first step in preparing for compliance. Below are some notable areas of focus:

- Air Quality: Regulations aimed at reducing air pollutants such as particulate matter, volatile organic compounds (VOCs), and greenhouse gases.

- Water Quality: Standards for wastewater discharge, including limits on pollutants like heavy metals, chemicals, and nutrients.

- Waste Management: Rules for the handling, storage, and disposal of hazardous waste materials, promoting recycling and waste reduction.

- Chemical Safety: Requirements for the safe use, storage, and reporting of chemicals used in manufacturing processes.

Staying informed about each of these key area is vital to anticipate and mitigate the Impact of the 2025 US Environmental Protection Agency (EPA) Regulations on Manufacturing.

Potential Economic Impacts on Manufacturers

The implementation of new EPA regulations can have various economic impacts on the manufacturing sector. Companies may face increased compliance costs, which can affect profitability and investment decisions. The Impact of the 2025 US Environmental Protection Agency (EPA) Regulations on Manufacturing may include both direct and indirect costs, which businesses must carefully assess.

Direct and Indirect Costs

One aspect of economic impact relates to costs incurred. It’s useful to understand the difference between direct and indirect costs:

- Direct Costs: These include expenses related to upgrading equipment, implementing new technologies, and training personnel to comply with the new regulations.

- Indirect Costs: These costs may arise from changes in production processes, increased administrative burdens, and potential delays in obtaining permits or approvals.

While some manufacturers may view environmental regulations as a burden, others see them as an opportunity to innovate and improve efficiency. Companies that proactively invest in cleaner technologies and sustainable practices may gain a competitive advantage.

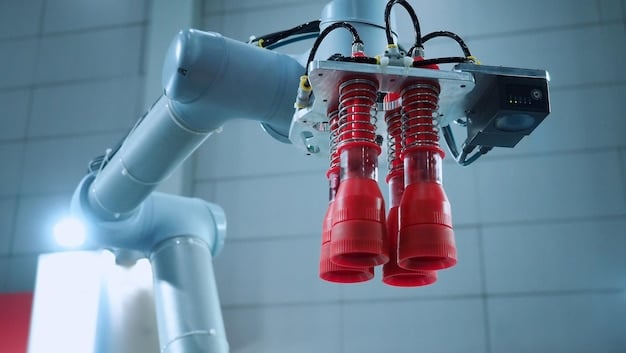

Technological Innovations for Compliance

To meet stricter environmental standards, manufacturers are increasingly turning to technological innovations. These advancements can help reduce emissions, improve resource efficiency, and minimize waste. As manufacturers navigate these evolving challenges, prioritizing cleaner technologies and sustainable practices can lead to distinct competitive advantages, illustrating the Impact of the 2025 US Environmental Protection Agency (EPA) Regulations on Manufacturing.

Examples of Innovative Technologies

These are some prominent examples that demonstrate the range of viable options:

- Advanced Filtration Systems: These systems can remove pollutants from air and water emissions more effectively than traditional methods.

- Smart Manufacturing: Utilizing data analytics and automation to optimize production processes, reduce energy consumption, and minimize waste.

- Green Chemistry: Designing chemical products and processes that reduce or eliminate the use and generation of hazardous substances.

Adopting these technologies not only helps manufacturers comply with regulations but can also lead to cost savings and improved operational performance, ultimately mitigating the Impact of the 2025 US Environmental Protection Agency (EPA) Regulations on Manufacturing.

Strategies for Manufacturers to Adapt

Adapting to the 2025 EPA regulations requires a proactive and strategic approach. Manufacturers should focus on assessing their current operations, identifying areas for improvement, and implementing strategies to enhance compliance and sustainability. This preparation is key to understanding the Impact of the 2025 US Environmental Protection Agency (EPA) Regulations on Manufacturing.

Key Adaptation Strategies

The following approaches will be key in the coming years:

- Conduct a Comprehensive Assessment: Evaluate current environmental performance and identify areas where improvements are needed to meet the new regulations.

- Develop a Compliance Plan: Create a detailed plan outlining the steps required to achieve compliance, including timelines, resource allocation, and performance metrics.

- Invest in Employee Training: Ensure that employees are well-trained on the new regulations and equipped with the knowledge and skills to implement sustainable practices.

The Role of Government and Industry Collaboration

Effective implementation of environmental regulations requires collaboration between government agencies, industry stakeholders, and research institutions. Government support can play a crucial role in helping manufacturers adapt to the new regulations. Industry collaboration can facilitate the sharing of best practices and the development of innovative solutions. By working together, stakeholders can mitigate the Impact of the 2025 US Environmental Protection Agency (EPA) Regulations on Manufacturing.

Government Support and Incentives

This support can take various forms, including:

- Financial Assistance: Grants, loans, and tax incentives to help manufacturers invest in cleaner technologies and sustainable practices.

- Technical Assistance: Programs that provide guidance and support to manufacturers in understanding and implementing the new regulations.

- Regulatory Flexibility: Allowing some flexibility in the implementation of regulations to accommodate the unique circumstances of different manufacturers.

| Key Point | Brief Description |

|---|---|

| 💰Increased Costs | Compliance requires investment in new tech and processes. |

| 🧪Tech Innovation | Advanced systems help reduce pollution and improve efficiency. |

| 🤝Collaboration | Government and industry must work together for effective regulation implementation. |

Frequently Asked Questions

The main objectives include reducing air and water pollution, improving waste management, and promoting safer chemical usage in manufacturing processes, all aimed at enhancing public and environmental health.

Manufacturers can begin by conducting thorough environmental assessments, developing detailed compliance plans, investing in employee training, and exploring technological innovations for cleaner production.

Government grants, loans, and tax incentives can provide financial assistance for manufacturers investing in cleaner technologies and sustainable practices to meet the 2025 EPA standards.

Technology is crucial, with advanced filtration systems, smart manufacturing techniques, and green chemistry playing significant roles in reducing emissions and improving overall resource efficiency.

While initial compliance may present challenges, in the long term, the Impact of the 2025 US Environmental Protection Agency (EPA) Regulations on Manufacturing encourages innovation and efficiency that can lead to reduced costs and improved competitiveness.

Conclusion

Navigating the Impact of the 2025 US Environmental Protection Agency (EPA) Regulations on Manufacturing requires a proactive and strategic approach. By understanding the regulations, adopting innovative technologies, and fostering collaboration, manufacturers can not only comply with the new standards but also enhance their long-term sustainability and competitiveness.

As the 2025 deadline approaches, staying informed and taking decisive action will be critical for manufacturers to thrive in an evolving regulatory landscape. Government and industry collaboration is essential to ensure a smooth transition and a more sustainable future for the US manufacturing sector.