US EPA Regulations: Impact on Manufacturing Compliance Costs

US Environmental Protection Agency (EPA) regulations significantly influence manufacturing compliance costs by imposing stringent standards for emissions, waste management, and chemical usage, necessitating substantial investments in technology and processes to adhere to these evolving rules.

The impact of US Environmental Protection Agency (EPA) Regulations: How New Rules Affect Manufacturing Compliance Costs is a critical concern for businesses nationwide. Understanding these regulations is essential for maintaining compliance and managing expenses effectively.

Understanding the US Environmental Protection Agency (EPA)

The US Environmental Protection Agency (EPA) plays a pivotal role in safeguarding the environment and public health across the United States. Established in 1970, the EPA is responsible for creating and enforcing environmental regulations. These regulations span various sectors, including manufacturing, and aim to minimize pollution, protect natural resources, and ensure a cleaner, healthier environment for all Americans.

The EPA’s authority is derived from several key environmental laws, such as the Clean Air Act, the Clean Water Act, and the Resource Conservation and Recovery Act (RCRA). These laws provide the legal framework for the EPA to set standards, issue permits, and enforce compliance. Understanding the EPA’s mission and the laws it administers is crucial for manufacturers, as compliance with these regulations can significantly impact their operations and costs.

EPA’s Core Responsibilities

The EPA’s main responsibilities include:

- Setting National Standards: Establishing benchmarks for air and water quality, as well as waste management practices.

- Enforcement: Monitoring compliance with environmental laws and taking action against violators.

- Research and Education: Conducting scientific research to better understand environmental issues and educating the public about environmental protection.

Historical Context of EPA Regulations

Over the decades, EPA regulations have evolved to address emerging environmental challenges. Early regulations focused on controlling major sources of pollution, while more recent rules tackle complex issues like greenhouse gas emissions and toxic chemical usage. This evolving landscape requires manufacturers to stay informed and adapt their practices to meet the latest standards.

The EPA’s influence is far-reaching, affecting everything from the types of chemicals used in production processes to the methods for disposing of waste. By understanding the EPA’s role and historical context, manufacturers can better anticipate future regulatory changes and proactively prepare for their impact.

In conclusion, the EPA’s primary focus is on environmental protection through regulation and enforcement, leading to significant changes in manufacturing practices. Adherence not only ensures legal compliance but also contributes to a more sustainable and responsible manufacturing sector.

Key EPA Regulations Affecting Manufacturing

Several key EPA regulations directly affect the manufacturing sector, each designed to address specific environmental concerns. These regulations often require significant investment and operational adjustments. Let’s explore some of the most impactful regulations and their specific requirements.

Understanding these regulations is crucial for manufacturers. Compliance ensures environmental protection, but also avoids costly penalties and legal repercussions.

Clean Air Act (CAA)

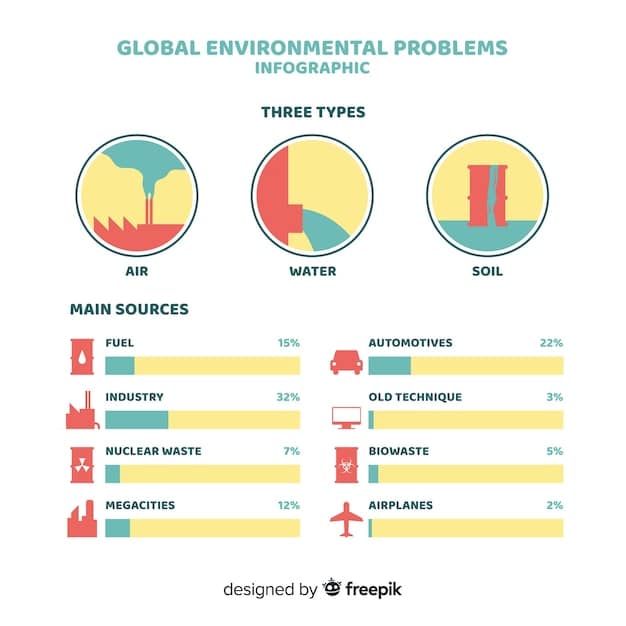

The Clean Air Act sets standards for air pollutants, including particulate matter, ozone, sulfur dioxide, and nitrogen oxides. Manufacturers must control emissions from their facilities to meet these standards, often requiring the installation of pollution control technologies like scrubbers and filters. Meeting CAA requirements can involve significant capital expenditures and ongoing operational costs.

Clean Water Act (CWA)

The Clean Water Act regulates the discharge of pollutants into waterways. Manufacturers must obtain permits for wastewater discharges and implement treatment technologies to remove pollutants before releasing water back into the environment. This can involve investing in advanced wastewater treatment systems and regularly monitoring discharge quality.

- Resource Conservation and Recovery Act (RCRA): Governs the management of hazardous waste, from generation to disposal.

- Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA): Addresses the cleanup of contaminated sites.

- Emergency Planning and Community Right-to-Know Act (EPCRA): Requires facilities to report on the storage, use, and release of hazardous chemicals.

Impact on Manufacturing Processes

These regulations impact various aspects of manufacturing, including:

- Chemical Usage: Restrictions on the use of certain chemicals require manufacturers to find safer alternatives.

- Waste Management: Proper handling and disposal of hazardous waste increase operational costs.

- Emissions Control: Technologies to reduce air and water emissions necessitate capital investments.

Complying with these EPA regulations is an ongoing process that requires continuous monitoring, adaptation, and investment. Manufacturers must integrate environmental considerations into their core business strategies to ensure long-term compliance and sustainability.

In summary, the Clean Air Act, the Clean Water Act, and other EPA regulations significantly influence manufacturing. By understanding these regulations and their requirements, manufacturers can take proactive steps toward compliance, mitigating risks and fostering environmental stewardship.

How New EPA Rules Increase Compliance Costs

Recent updates to EPA regulations are placing additional financial burdens on manufacturers. These new rules often require more stringent standards and advanced technologies, leading to increased compliance costs. Let’s examine some specific examples of how these costs are rising.

Staying informed about these changes is crucial. Manufacturers need to understand the specific requirements of new rules to effectively manage their compliance costs and avoid penalties.

Stricter Emission Standards

New emission standards for pollutants like greenhouse gases and volatile organic compounds (VOCs) are driving up compliance costs. Manufacturers may need to invest in new equipment or processes to reduce emissions to the required levels. This can include upgrading existing pollution control technologies or implementing entirely new systems.

Enhanced Monitoring and Reporting Requirements

The EPA is increasingly requiring more detailed and frequent monitoring of emissions and discharges. This can involve installing continuous monitoring systems and submitting regular reports to the agency. The costs associated with monitoring and reporting can be substantial, particularly for smaller manufacturers with limited resources.

Increased Enforcement and Penalties

The EPA has been stepping up its enforcement efforts, increasing the risk of penalties for non-compliance. Penalties for violating environmental regulations can be significant, potentially including fines, legal fees, and even facility shutdowns. This increased enforcement pressure is driving manufacturers to invest more in compliance to avoid these costly repercussions.

Examples of Cost Increases

- Upgrading Air Pollution Control Equipment: Costs can range from tens of thousands to millions of dollars.

- Implementing Advanced Wastewater Treatment Systems: Similar costs, depending on the type and complexity of the system.

- Hiring Environmental Compliance Staff: Ongoing salaries and benefits for specialized personnel.

To mitigate these rising compliance costs, manufacturers should consider:

- Conducting Regular Environmental Audits: Identifying potential compliance gaps early on.

- Investing in Energy Efficiency: Reducing emissions and lowering energy bills.

- Seeking Government Incentives: Exploring grants, tax credits, and other financial assistance programs.

In conclusion, new EPA rules are increasing compliance costs for manufacturers through stricter standards, enhanced monitoring, and increased enforcement. Proactive measures and strategic investments can help manufacturers manage these costs and ensure long-term compliance.

Strategies for Manufacturers to Minimize Compliance Costs

Manufacturers can employ several strategies to minimize the financial impact of EPA regulations. These strategies involve a combination of proactive planning, technological investment, and operational efficiencies. Let’s explore some effective approaches for managing compliance costs.

Strategic planning is essential. By anticipating regulatory changes and implementing cost-effective solutions, manufacturers can reduce their financial burdens and maintain a competitive edge.

Conducting Regular Environmental Audits

Regular environmental audits can help identify potential compliance gaps and areas for improvement. These audits involve a comprehensive review of a facility’s operations, processes, and environmental performance. By identifying and addressing issues early on, manufacturers can avoid costly penalties and ensure ongoing compliance.

Investing in Energy Efficiency

Energy efficiency measures can reduce emissions and lower energy bills, providing a double benefit for manufacturers. This can include upgrading equipment, improving insulation, and optimizing processes to reduce energy consumption. Energy-efficient technologies not only reduce environmental impact but also lower operational costs.

Adopting Cleaner Production Technologies

Cleaner production technologies use fewer resources and generate less waste, reducing both environmental impact and compliance costs. This can involve switching to safer chemicals, implementing closed-loop systems, and optimizing production processes to minimize waste generation. Cleaner production can lead to significant cost savings over time.

Seeking Government Incentives and Assistance

Various government incentives and assistance programs are available to help manufacturers comply with EPA regulations. These can include grants, tax credits, loan programs, and technical assistance. By seeking out and utilizing these resources, manufacturers can offset some of the costs associated with compliance.

- Grant Programs: Financial assistance for specific projects, such as upgrading equipment or implementing new technologies.

- Tax Credits: Reductions in tax liabilities for investments in energy efficiency or pollution control.

- Loan Programs: Low-interest loans for environmental compliance projects.

Training and Education

Investing in training and education for employees can improve environmental performance and reduce the risk of non-compliance. Well-trained employees are more likely to follow proper procedures, identify potential issues, and implement effective solutions. This can lead to cost savings through reduced waste, improved efficiency, and avoided penalties.

In conclusion, manufacturers can minimize compliance costs through strategic planning, technological investment, and operational efficiencies. By conducting regular audits, investing in energy efficiency, adopting cleaner production technologies, and seeking government assistance, manufacturers can reduce their financial burdens and ensure long-term compliance.

The Role of Technology in Reducing Compliance Costs

Technology plays a crucial role in helping manufacturers reduce compliance costs and improve environmental performance. Advanced technologies can automate monitoring, optimize processes, and reduce emissions, leading to significant cost savings. Let’s explore some key technological solutions.

Staying updated with technological advancements is vital. By adopting innovative solutions, manufacturers can streamline their compliance efforts, reduce costs, and enhance their environmental stewardship.

Advanced Monitoring Systems

Advanced monitoring systems can continuously track emissions and discharges, providing real-time data on environmental performance. These systems can automate reporting, identify potential issues, and ensure compliance with regulatory requirements. Continuous monitoring can reduce the need for manual inspections and lower the risk of non-compliance.

Data Analytics and Predictive Modeling

Data analytics and predictive modeling can help manufacturers optimize processes, reduce waste, and improve energy efficiency. By analyzing data on production, energy consumption, and emissions, manufacturers can identify opportunities for improvement and implement targeted solutions. Predictive modeling can anticipate potential issues and enable proactive intervention.

Automation and Robotics

Automation and robotics can improve efficiency, reduce waste, and minimize the risk of human error in manufacturing processes. Automated systems can perform tasks more consistently and accurately than humans, leading to reduced waste and improved environmental performance. Robotics can handle hazardous materials and perform tasks in dangerous environments, reducing the risk of worker exposure and environmental contamination.

- Cloud-Based Environmental Management Systems (EMS): Centralized platforms for tracking and managing environmental data.

- Digital Twins: Virtual models of physical assets for simulating and optimizing performance.

- Internet of Things (IoT) Sensors: Real-time data collection for monitoring environmental conditions.

Case Studies of Successful Technology Implementation

Several manufacturers have successfully implemented technology to reduce compliance costs and improve environmental performance. For example, a chemical plant installed an advanced monitoring system that reduced emissions by 20% and lowered compliance costs by 15%. A food processing facility implemented a data analytics platform that optimized water usage and reduced wastewater discharge by 10%.

In conclusion, technology is a powerful tool for reducing compliance costs and improving environmental performance in manufacturing. By investing in advanced monitoring systems, data analytics, automation, and other technological solutions, manufacturers can streamline their compliance efforts, reduce costs, and enhance their environmental sustainability.

Future Trends in EPA Regulations and Manufacturing

The future of EPA regulations and their impact on manufacturing is likely to be shaped by emerging environmental challenges and technological advancements. Anticipating these trends is crucial for manufacturers to proactively prepare for future compliance requirements and opportunities.

Adaptability is key. By staying informed and embracing innovative solutions, manufacturers can thrive in an evolving regulatory landscape and contribute to a more sustainable future.

Increased Focus on Climate Change

Climate change is expected to be a major driver of future EPA regulations. The agency is likely to increase its focus on reducing greenhouse gas emissions and promoting energy efficiency. Manufacturers may face stricter regulations on carbon emissions and be required to invest in renewable energy sources and energy-efficient technologies.

Emphasis on Environmental Justice

Environmental justice, which aims to ensure that all communities have equal protection from environmental hazards, is also likely to play a more prominent role. The EPA will likely focus on addressing environmental issues that disproportionately affect low-income and minority communities, potentially leading to stricter regulations in these areas.

Use of Data and Technology

The EPA is expected to increase its use of data and technology to monitor compliance and enforce regulations. This can include remote sensing, data analytics, and artificial intelligence. Manufacturers may need to invest in advanced monitoring systems and data management capabilities to comply with these evolving requirements.

- Circular Economy Initiatives: Promoting waste reduction and resource reuse.

- Chemical Safety Regulations: Stricter rules on the use and disposal of hazardous chemicals.

- Water Scarcity Measures: Regulations to conserve water and protect water resources.

Preparing for the Future

To prepare for these future trends, manufacturers should:

- Stay Informed: Monitor regulatory developments and emerging environmental issues.

- Invest in Innovation: Explore new technologies and sustainable practices.

- Engage with Stakeholders: Collaborate with regulators, communities, and other stakeholders to address environmental challenges.

In conclusion, future trends in EPA regulations and manufacturing will be shaped by climate change, environmental justice, and technological advancements. By proactively addressing these trends, manufacturers can ensure long-term compliance, reduce costs, and contribute to a more sustainable future.

| Key Point | Brief Description |

|---|---|

| 🏭 EPA Regulations | EPA sets environmental protection standards affecting air, water, and waste management. |

| 💰 Compliance Costs | New rules increase costs due to stricter standards and monitoring requirements. |

| ✅ Minimizing Costs | Strategies include audits, energy efficiency, and cleaner technologies. |

| 🌱 Future Trends | Expect more focus on climate change, environmental justice, and technology. |

Frequently Asked Questions (FAQ)

▼

The EPA’s main role is to protect human health and the environment by enforcing regulations based on laws like the Clean Air Act and Clean Water Act.

▼

EPA regulations can increase costs by requiring investments in pollution control equipment, monitoring systems, and cleaner production technologies.

▼

Strategies include conducting regular environmental audits, investing in energy efficiency, and adopting cleaner production technologies to reduce waste and emissions.

▼

Technology aids by automating monitoring, optimizing processes with data analytics, and reducing emissions through advanced systems, enhancing compliance efficiency.

▼

Future trends include a greater emphasis on addressing climate change, promoting environmental justice, and utilizing data and technology for better regulation.

Conclusion

Understanding the impact of US Environmental Protection Agency (EPA) regulations on manufacturing compliance costs is crucial for businesses. Staying informed, adopting cost-effective strategies, and embracing technological advancements are key to navigating the evolving regulatory landscape and fostering environmental stewardship. By proactively addressing these challenges, manufacturers can ensure long-term compliance and contribute to a more sustainable future.